The screw pump is a rotating pump that relies on the adjustment of the meshing room developed by the pump body and also the screw to relocate the fluid or to pressurize it. The screw pump by screw number is divided right into a single screw pump, twin screw pump, as well as the three-screw pump. When the active screw is turned, the driven screw is involved with the driven screw, as well as the screw meshing room at one end of the suction chamber is progressively boosted and the stress is decreased.

The liquid enters the meshing space under pressure. When the quantity is made the most of to develop a closed chamber, the fluid is continually moved axially in one secured chamber until it is discharged to one end of the chamber. Currently, the screw-engaging room at one end of the discharge chamber is progressively lowered, and also the liquid is released.

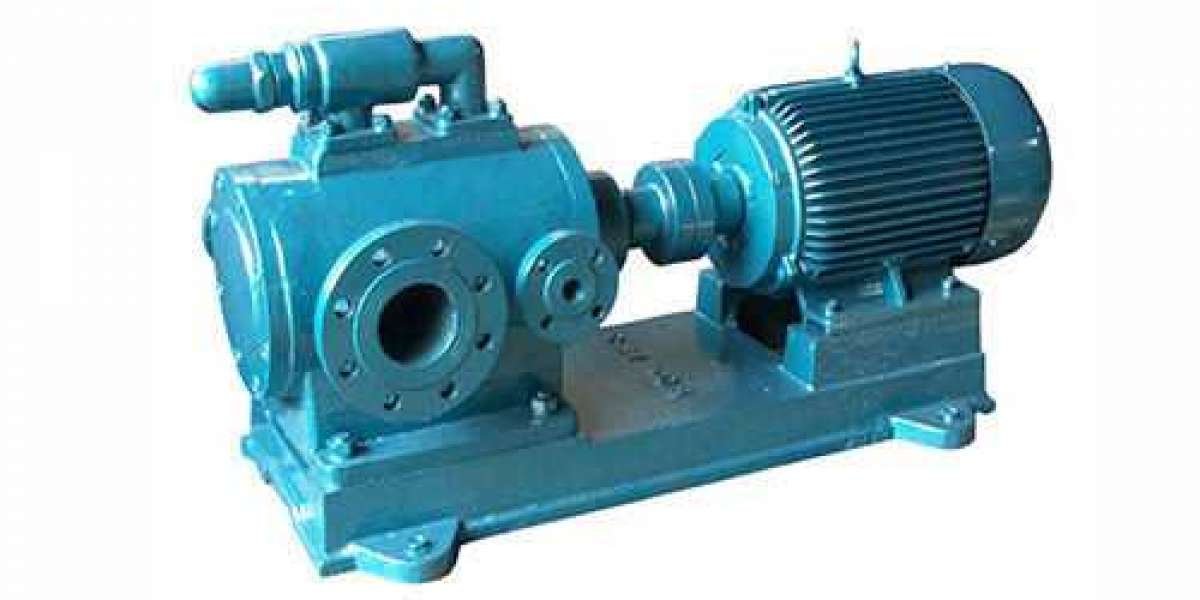

The functioning concept of the screw pump is similar to that of the equipment pump, other than that the equipment is replaced by a screw on the framework. Table for a range of screw pump functions as well as application array. Screw pump flow and pressure pulse are tiny, sound as well as resonance, self-absorption capacity, but the screw handling is harder. The pump has a solitary suction as well as a dual suction type, but the single screw pump has only a solitary suction type. The pump has to be geared up with a safety valve (single screw pump not called for) to prevent damage to the pump or prime mover as a result of some reason such as discharge of the pump so that the outlet stress of the pump surpasses the permissible worth. Twin Screw Pump

Architectural Characteristics and also Performance of Twin Screw Pump

1, Twin-screw pump has a high suction ability;

2, Twin-screw pump can be pulseless constant liquid and also no blending, emulsification sensation;

3, Double screw pump framework of an overall of horizontal, bracket, vertical, and so on;

4, According to the requirements of the transmission medium, a twin-screw pump device can offer a heating or cooling framework;

5, The use of independent lubrication of the exterior bearings, permitting the delivery of different non-lubricating media;

6, Medium viscosity: 1-1500mm2/ s, minimize the speed viscosity can reach 3X106mm2/ s;

7, The pressure range: ≤ 4.0 MPa 8, the circulation range: 1-2000m3/ h 9, twin-screw temperature array: -15 ~ 200.

Twin-screw pump use

1, Used in chemical petrochemical and also food industry for loading, communicating, and also supplying pumps;

2, Used in the ship for transmission, pressurization, gas shot, and lubricating oil pump and also marine hydraulic pump;

3, Used in the home heating devices for gas injection, fuel supply, and pump;

4, Used in the machinery industry as hydraulic, lubrication, as well as motor pumps;

5, Used in the food market for the delivery of alcohol, honey, sugar juice, toothpaste, milk, butter, soy sauce, grease, animal oil, wine, and so on;

6, In the textile, paper, environmental protection industry for the transmission of fiber fluid, viscose liquid, pulp black liquor, sewer, seawater, mortar, and also various other media. Twin Screw Pump

The screw pump is a rotary pump that counts on the modification of the meshing room developed by the pump body as well as the screw to relocate the liquid or to pressurize it. The screw pump by screw number is split into a single screw pump, twin-screw pump, and three-screw pump. The functioning concept of the screw pump is similar to that of the equipment pump, other than that the gear is changed by a screw on the framework. The pump has a solitary suction and also double suction type, however, the single screw pump has only a single suction kind. The pump must be furnished with a security shutoff (solitary screw pump not required) to stop damage to the pump or prime mover due to some factor such as discharge of the pump so that the electrical outlet pressure of the pump goes beyond the acceptable worth.